Graphene applications: AEROGrAFT

The Graphene Flagship's AEROGrAFT spearhead project’s graphene-based smart filters provide cleaner air and offer a more sustainable solution for in-flight air filtration.

Most aircraft in flight today use HEPA filters. These high-efficiency particulate air filters work like a mechanical net to remove dust, bacteria and other particulate matter from the air. However, HEPA filters are unable to capture volatile organic compounds, as they are airborne gases rather than particles, which are about 1000 times too small to be trapped in the filter. Not only this, but HEPA filters require frequent maintenance and regular replacement, resulting in additional costs and waste.

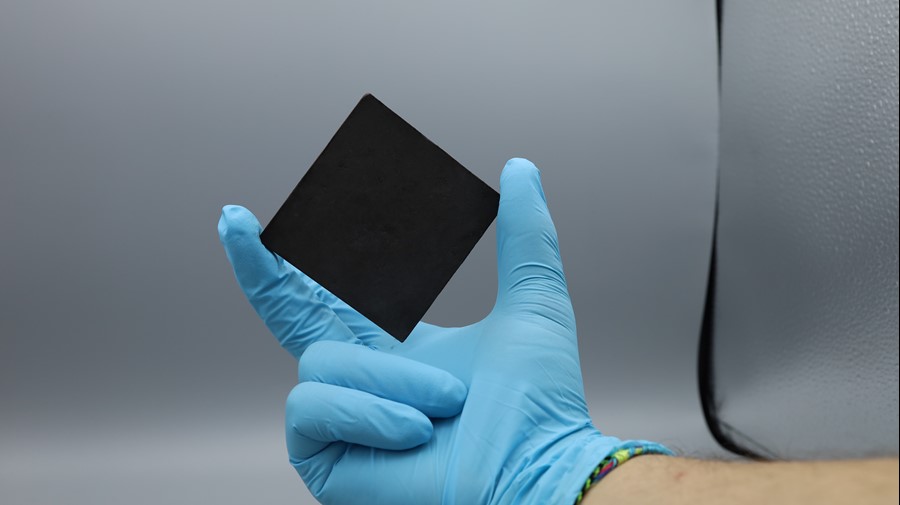

Now, thanks to graphene, AEROGrAFT’s filters can effectively capture these volatile organic compounds, as well as particulate matter, dust and bacteria, providing a cleaner flow of air to the cabin. The filter is made by coating a porous ceramic network with graphene over a removable template. This results in a material composed of hollow graphene nanotubes with a very high internal surface area. Graphene’s strong affinity for organic compounds, combined with its high surface area, means it can effectively trap volatile organic compounds, unlike HEPA filters.

The graphene filters also feature a unique self-cleaning functionality. They clean themselves by heating to 300 °C, which also kills any bacteria, microorganisms, spores and fungi that may have accumulated. Graphene’s high chemical resistance towards oxidation enables the filter material to withstand such high temperatures. Furthermore, the hollow graphene tubes’ super-low density dramatically reduces the filter’s heat capacity, meaning less energy is needed for cleaning. Their large surface area also enables efficient heat transfer to other organic pollutants, like microorganisms.

AEROGrAFT are developing a combined electronic smart filtration system using this technology. The system will consist of the graphene-based filter unit paired with an electronic control panel to monitor the filter’s key parameters and control the smart functions. The AEROGrAFT filters have the potential to replace HEPA filters in commercial aircraft to improve cabin air quality and shorten the downtime required for maintenance and cleaning, as well as reducing maintenance costs and waste.

AEROGrAFT's filter is made by coating a porous ceramic network with graphene over a removable template.

AEROGrAFT’s high-efficiency particulate air filters work like a mechanical net to remove dust, bacteria and other particulate matter from the air.