Product Gallery

Graphene enabled products

Graphene is being used to enable the next generation of technology: from interconnects for 5G data communication to wearable health monitors, and even flexible mobile screens. About 90 products (mainly business-to-business products) have come out of the Graphene Flagship since 2013. Here is a small selection of them.

Graphene product videos

Graphene product gallery

Marigi racing thermal coating

The RIXON-003 graphene-based coating improves the thermal dissipation performance of racing components such as brake calipers and radiators, and has been applied in official motorcycle world championship competitions (Superbike and MotoGP). With a micrometric thickness, this coating can be applied to various metallic materials on non-friction surfaces, achieving improved thermal diffusion resulting in 20-25% thermal dissipation reduction.

Find out more

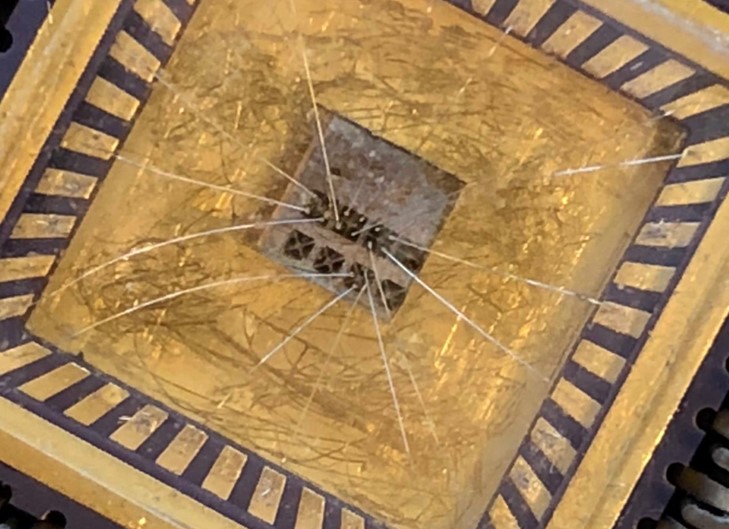

Graphene Hall sensor GHX-1

The Graphene Hall sensor, GHX-1, detects magnetic fields and outputs an analog signal proportional to the intensity of the field. Hall sensors made with epitaxial graphene show sensitivities to magnetic fields 10x greater than silicon-based Hall sensors, and record-low magnetic field detection limits when compared to other semiconductors and graphene-based Hall magnetometers. The performance prevails up to temperatures T= 150 °C.

Find out more

Sixonia’s G-DISP series

Sixonia’s G-DISP series is a range of dispersions of functionalised, large-flake, high-quality few-layer graphenes in various solvents such as water and N-Methyl-2-pyrrolidone (NMP). The functionalization of E-Graphene at the edges results in an easy-to-use product, providing high film conductivities directly after application without the need for surfactants, chemical or thermal post-treatment. Custom dispersions can be produced depending on customer-specific requirements, upon request.

Find out more

GXT - Graphene inks

GXT-ink is suitable for printing geometric paths on different types of substrates and biopolymers like PLA with a sheet resistance as low as 4 Ohm/sq/mil. The printed path can be laminated with common plastic films without damaging the electrical properties, and printed circuits on PET film remained stable during high stress conditions.

Find out more

GXT - Graphene lubricant

GXT-Lubricant utilises graphene to produce a class of oils and dry-to-touch coating which reduce friction, heat, and wear between mechanical components. Graphene can replace some toxic and hazardous components found in traditional oils.

Find out more

Vibora King Cobra 2019

Vibor-A presents the Vibora King Cobra 2019; a high-quality diamond shaped padel racket designed for advanced and professional players. A graphene frame ensures maximum flexibility and durability, and the excellent heat conduction properties of graphene enable blades with high recovery capacity, greatly reducing vibrations.

Find out more

Graphene Motorcycle Helmet

Researchers from IIT and Italian design company Momodesign incorporated graphene into the exterior shell of this helmet as a coating. This coating allows better distribution of impact force and the excellent heat-conductive properties of the graphene dissipate heat quickly across the helmet, protecting the inner materials from thermal degradation. The result is a helmet with improved thermal comfort and safety.

Find out more

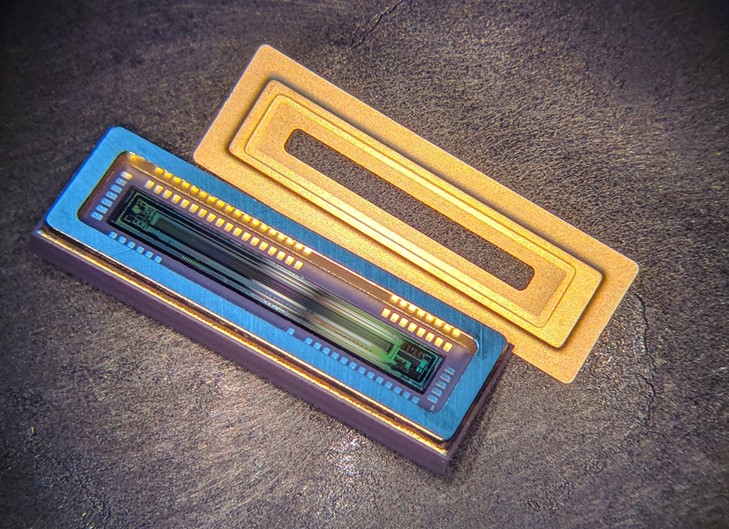

VIS-SWIR Linear Array Detector

Emberion introduces a novel cost-competitive graphene-based linear array sensor with tailor made CMOS read-out circuits. The product detects Vis-SWIR spectral range (400 – 1800 nm extending up to 2000 nm) designed primarily for spectrometers. The 512 x 1-pixel linear array provides consistent responsivity with very low noise and high dynamic range over a broad spectrum.

Find out more

Cambridge Graphene Inks

Cambridge Graphene uses a scalable production process for its graphene ink, developed at the Cambridge Graphene Centre, University of Cambridge. The process allows for a range of ink formulations to be manufactured in order to meet the requirements of different printing methods and substrates. Currently, all Cambridge Graphene inks are aqueous, environmentally friendly and non-toxic.

Find out more

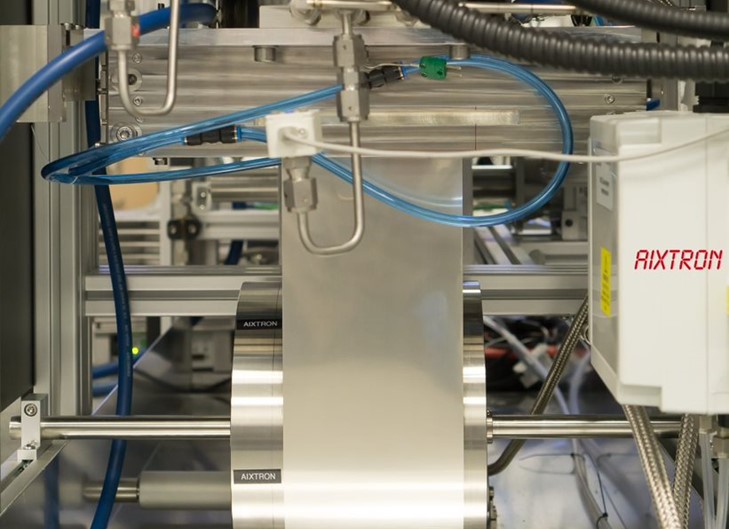

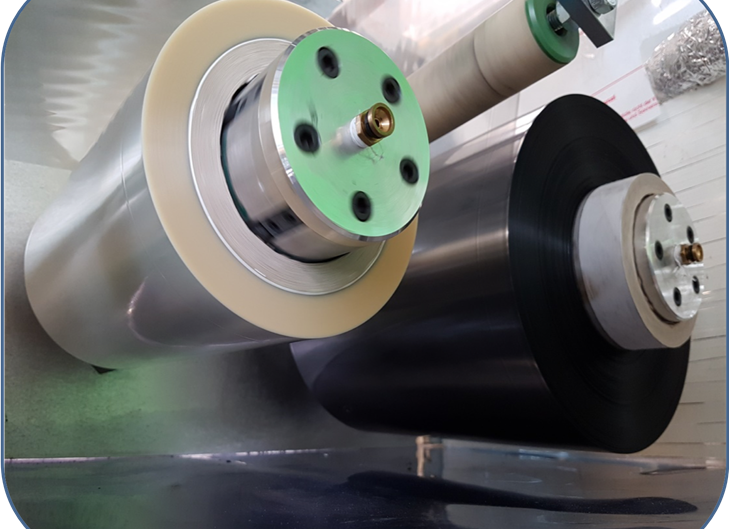

Neutron

The Neutron is the first roll to roll system capable of depositing large area graphene onto metal foils under ambient conditions. Since the Neutron does not require a vacuum, it can be easily placed inline at manufacturing, enabling truly cost-effective graphene production.

Find out more

CCS

The CCS is the reactor of choice for leading universities, R&D institutes and industry for growing world-class 2D nanomaterials. The platform uses AIXTRON’s scalable shower-head and heating technology to enable the growth of 2D materials onto wafers without requiring a catalyst.

Find out more

Corsa Graphene 2.0

Corsa is the tire of choice for professional riders in the peloton. Manufactured with premium cotton casing to conform closer to the road’s surface, and to provide a smoother ride, easier rolling, and better grip. Four compounds in the tread (4C) and GRAPHENE 2.0 allow for higher speed, increased wear life, lower resistance, and improved grip.

Find out more

Mediadevil CB-01 Earphones

MediaDevil’s CB-01 earphones, compatible with any 3.5 mm connector jack port, are manufactured with a graphene coating called Nanene® Graphene-Enhanced Audio. Nanene enables the production of an earphone diaphragm that is thinner and more flexible than one from traditional materials, enhancing both the high-end (treble) and the low-end (bass) of the audio frequency wave.

Find out more

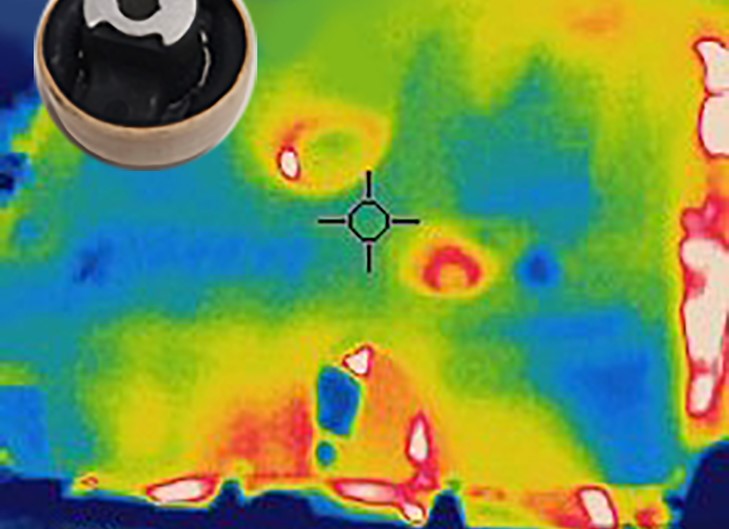

AVANGRM rubber for thermal dissipation

AvanGRM-rubber integrates graphene materials with rubber; a polymer with traditionally low levels of thermal conductivity. The use of graphene in rubber-based components, such as housing in automotive components, increases heat dissipation and ultimately results in higher thermal conductivity, greater product shelf life, and improved performance.

Find out more

Elesia Air Cooling Unit

The Elesia Air Cooling Unit EL-ACU-1000 features an innovative approach in the design of high-performance air conditioning. Nanesa produced the evaporator and condenser unit through modern nanotechnology, using aluminium foam slices covered with a graphene-copper coating. These two components act as heat sinks, resulting in a compact system with exceptional efficiency (η>150%, compared to conventional systems).

Find out more

GXT Electrostatic discharge bags

GNext has developed a unique technology that enables the production of wlectrostatic discharge (ESD) bags for electronics devices with graphene. Replacing metals such as aluminium with graphene allows the bags to be recycled as pure polymer. Environmental and economic costs of those products are increasing, but with greener processes, it is now possible to save money and make a sustainable investment.

Find out more

GXT Graphene coating

GNext is able to apply a thin multilayer coating of graphene over a wide range of polymeric films, achieving different degrees of transparency. Our versatile system is compatible with continuous production using industry-level techniques. The thickness of the graphene multilayers ranges from 10 nm to tens of microns, is uniform on a large scale, and stable in harsh conditions of temperature and pressure.

Find out more