Standardisation

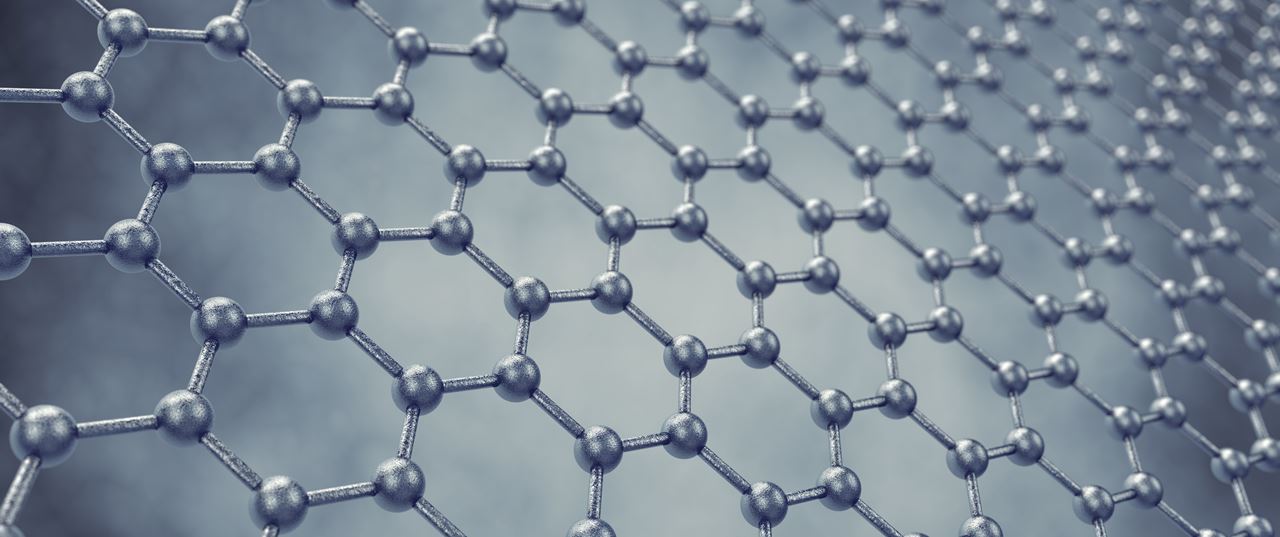

Standardising graphene and layered materials will lower the barrier to entry for innovation, commercialisation and industrialisation in the field.

Senior Researcher at Karlsruhe Institute of Technology and Manager of the Graphene Flagship Standardisation Committee

The further commercialisation of materials and technologies based on graphene and related materials, as well as the establishment of robust, underlying value networks, remain a challenge. Industry has identified that the lack of standardised materials, processes and characterisation methods are important factors that slow down innovation in the field.

The Graphene Flagship Standardisation Committee seeks to overcome this challenge.

Why standardise graphene and related materials?

Firstly, which of the properties of graphene, or a related layered material, do I need to know and control in order to reliably achieve the desired function in my application? And secondly, which supplier can guarantee that their raw material meets my specifications in every single batch of production?

The first question is often surprisingly hard to answer. For example, in the case of polymer composites where graphene is used as a filler, factors like flake size, surface functionalisation, lattice defects, aggregation behaviour, the method of material processing and many more have a decisive impact on the performance of the composite.

Additionally, finding a supplier who can meet all these specifications can also be a challenge. Standardisation lays the basis for solving these issues: it will help us to enable better quality control, improve reliability and establish more trust in our communities. Furthermore, standardising graphene and layered materials will lower the barrier to entry for innovation, commercialisation and industrialisation in the field.

Our mission

Our work on standards in the field of graphene and layered materials focuses on:

- Characterisation methods

- Sample preparation

- Data analysis

- Terminology

We have 35 projects leading to standards or technical specifications. Various measurement and characterisation methods are being addressed, including:

- Level of disorder, number of layers (Raman)

- Specific surface area (BET)

- Structural properties (TEM, SEM, AFM)

- Electrical properties (various methods)

Within accompanying projects (such as EMPIR and VAMAS), interlaboratory comparisons and round-robin tests are being conducted, and new methods are being developed.

Our team

Check out the full list of members of the Graphene Flagship Standardisation Committee below, in addition to their affiliations and expertise in characterisation or measurement techniques.

| Name | Affiliation | Expertise |

| Dr Thurid Gspann |

Karlsruher Institut für Technologie, Institut für Nanotechnologie |

Raman, SEM, TEM, tensile testing, TGA, EDX and EELS |

| Dr César Merino |

Grupo Antolin Ingeniería, S.A. |

XRD, TEM, BET, Raman spectroscopy, SEM, TG and EA |

| Mr Guillaume Fievez |

Sonaca S.A. |

Mechanical characterization for aeronautical end-use cases |

| Prof Peter Boggild |

Technical University of Denmark |

Micro four-point probe metrology, THz-TDS conductivity and mobility metrology |

| Dr Félicien Schopfer |

LNE |

Partner of the Graphene Flagship Validation Service |

| Dr Raul Arenal |

University of Zaragoza |

Electron microscopy, electron spectroscopy, EELS, HR(S)TEM and XPS |

| Prof Costas Galiotis |

Foundation of Research for Technology, Institute of Chemical Engineering Sciences |

Raman spectroscopy, AFM, and mechanical properties |

| Prof Vladimir Fal'ko |

University of Manchester |

Transport, optics and microwaves |

| Prof Jari Kinaret |

Chalmers University of Technology |

Director of the Graphene Flagship |

| Prof Andrea Carlo Ferrari |

University of Cambridge |

Raman spectroscopy |

| Dr Manuela Melucci |

CNR |

Synthesis, functionalization and composites |

| Dr Norbert Fabricius |

International Standards Consulting GmbH & Co. KG |

Broad expertise |

| Dr Steven Brems |

IMEC |

Electrical characterization (mobility, SS, Vth...), PL, Raman, scanning probe techniques, XPS, RBS and more |

| Dr Christian Punckt |

Karlsruher Institut für Technologie, Institut für Nanotechnologie |

Standardisation, nanomaterial characterisation, printed electronics and graphene synthesis |

| Dr Matthieu Paillet |

Université de Montpellier |

Raman spectroscopy and optical reflectance |

| Dr Sandro Mignuzzi |

University of Cambridge, Cambridge Graphene Centre |

Raman spectroscopy |

| Dr Julio Gomez |

Avanzare Innovacion Tecnologica S.L. |

SEM, TEM, Raman spectroscopy, X-ray spectroscopy, mechanical and electrical properties, XPS and BET |

| Dr Amaia Zurutuza |

Graphenea |

Raman, SEM, probe station, optical microscopy, etc. |

| Prof Peter Uhd Jepsen |

Technical University of Denmark |

Terahertz spectroscopy and electrical conductivity measurements |

| Dr Alex Jouvray |

Aixtron Ltd |

Raman spectroscopy and optical microscopy |

Setting standards

This brochure gives you an overview of international standardisation, the activities of the Graphene Flagship Standardisation Committee (GFSC), graphene-related projects in IEC and ISO and the benefits of participating in developing standards as a tool for innovation.